There is no doubt that the flexibility of the concrete pole will reveal the size and strength of the steel rods inside it even though it is covered by the concrete. This practice is mostly employed by the experts who deals on concrete poles business and the supplying agents to a licensed electrical contractor in Nigeria.

The best way to check this is by allowing the loading of the poles on the truck that will convey it, bringing about 20feet out from to truck such that it suspends itself on the air without any support, if the pole is flexible it will start fluctuating up and down on the part that is on the air, also you will observe a tilt of that edge toward the ground the bigger the tilt the more flexible the pole possesses.

Another way to know the flexibility is by fixing the two edges at a rigid position may be concrete walls and using a hydraulic jack to push it at the center, at that instant the measure of the tilting of the center of that pole is its flexibility, though flexibility cannot be avoided in a concrete pole but when the ratio exceed a reasonable amount it shows the potential for easy damage in the future.

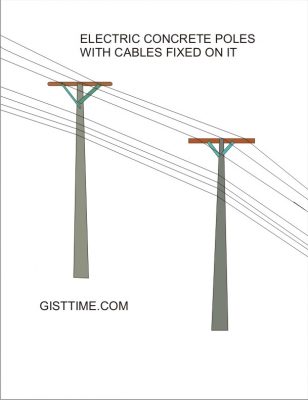

Concrete poles are among the major apparatus used in the distribution of electric power by the power stations and their distribution companies in many African countries. the concrete pole records of effectiveness in electric power management has encouraged its use for many countries across Africa.

These concrete poles are basically made with the mixture of sand, cement, granites or limestones, and steel rods to give it its strength. The use of these poles has encouraged external or surface wiring method as against the modern underground cables used by many developed countries.

Meanwhile, due to some short comings in the manufacturing of the concrete poles, many of the poles had been seen falling down at any little accidental force on it such as car hitting it, falling trees nearby, heavy rainfall with high breeze, and collapsed building, etc. even though that these poles were being tensioned on the ground to support its strength

. Some of the fallen poles are actually of high quality the reason for their fall may just be that the impact force they received that moment was so high that it exceeded their calculated tensile strength. While others fall at a little impact force due to their sub-standard contents.

The demand for the concrete poles is increasing every day following the development that is penetrating into many places and those places needs electricity supply, and the concrete poles is one of the major way to channel the distribution lines to those areas. Hence; the power distributions companies due purchase them as well as individuals who needs to direct the distribution lines to their houses.

The need to identify the original concrete poles from the sub-standard types has become very necessary due to the reason mentioned above, and from a little research concerning these concrete poles below are the things you need to consider, check and do on any concrete poles before buying it;

CHECK FOR VISIBLE INJURIES

As a Non-Destructive Test Inspector I believe that visual inspection results is among the most reliable report in the NDT work, therefore taking a very close look at the concrete poles to check if there is any form of injury like cracks, porosity, and inhomogeneous mixture of the concrete, if there is any of these faults on the body of the electric poles, it is probably indicating poor standard and hence, should not be accepted under contract condition, because any damage to any of the poles will start at those injuries. Therefore visual inspection is the first step.